What is a Photocatalyst (photocatalysis, photocatalytic action)?

Photocatalyst is the creation of a strong oxidation agent to breakdown any organic matter to carbon dioxide and water in the presence of the photocatalyst, light and water. The word 'photocatalysis' is actually composed of two parts, "photo" and "catalysis". 'Photo' is the Greek word for 'light' and 'Catalysis' is the process where a substance participates in modifying the rate of a chemical transformation of the reactants without being altered or consumed in the end.

Examples of the functions of a photocatalyst:

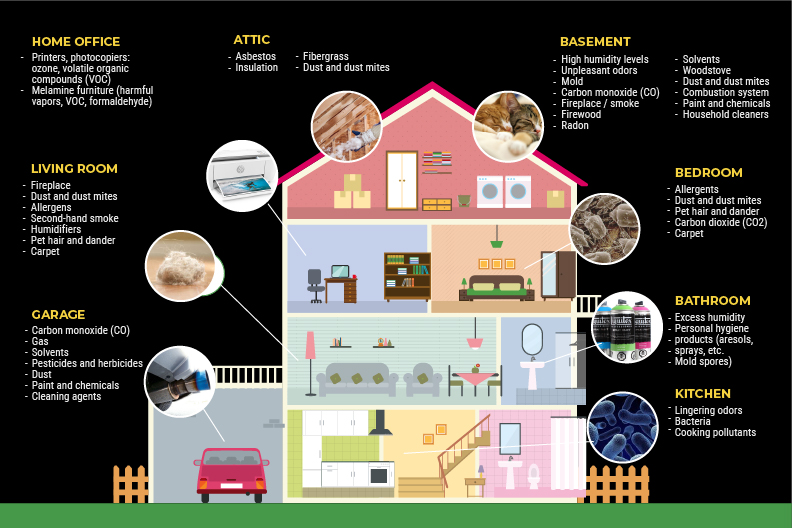

Air Purification - Oxidizes VOCs such as ethylene, formaldehyde, NOx, and SOx, allergen elimination, improves air quality. Sources of Volatile Organic Compounds (VOCs)-

Deodorizing - Oxidizes aldehyde, ammonia, chloroform, diesel, garbage, pest infestation, pet smells, etc.

-

Sanitizing - Destruction and prevention of moulds, fungi, algae growth, etc. through oxidation.

-

Self cleaning - Superhydrophilic properties help eliminate oil residue, soil, water stains,and other oxidized particles.

What is Nanotechnology?

Nanotechnology is a rapidly growing science in the production and utilization of particles that measure in nanometers. The term 'nanoparticles' is generally used to indicate particles with dimensions less than 100 nanometers. (1nm = 0.000000001m)

For comparison, a human hair is between 50,000 to 100,000nm in diameter, while a smoke particle is about 1,000nm in diameter.

How safe is TiO2?

TiO2 is the most widely used white pigment because of its brightness and very high refractive index in which is not surpassed by many other materials. Approximately 4 million tons of TiO2 are consumed worldwide annually.

It is used as a pigment to provide whiteness and opacity to products such as paints, coatings, plastics, papers, inks, foods, medicines (i.e. pills and tablets) as well as most toothpastes. TiO2 is also utilized to whiten skim milk; this has also been shown to increase the milk's palatability.

Does TiO2 effect or stain the treated surface?

No, it becomes a part of the surface it is applied to and is totally invisible. There will be no staining if TiO2 is used and applied as recommended.

Does a TiO2 treatment change the hardness and the feel of the surface?

Surfaces with TiO2 nanoparticles applied to them have an added hardness of approx. 4H to 5H (pencil grade) after curing. Even treated fabrics and textiles do not change their feel after being treated.

Do TiO2 nanocoatings work with artificial light in indoor-areas?

Yes, dependent on the size of the nanoparticles. When it comes to photocatalytic capabilities, the smaller the nanoparticle, the better. As long as there is natural or artificial lighting, the photocatalytic process occurs.

How does TiO2 work?

TiO2 contains valuable properties in its nanoscale size. As a micro crystal TiO2 is a super-hydrophilic photocatalyst. This is the basis of the self-cleaning, air-cleaning properties, and the many other features of TiO2. A light source (natural or artificial) generates UV, which strikes the TiO2 coated surface and reacts, creating the oxidant which reacts with particles that comes in contact with it. Microscopic particles, VOCs (volatile organic compounds) like formaldehyde, benzene, etc., as well as odours are oxidized, leaving behind only water and carbon dioxide.

How does the intensity of light affect the ability of TiO2 to create oxidizers that can purify the air?

As a characteristic of titanium dioxide, it starts to produce an oxidizer when exposed to ultraviolet rays of 400nm range or lower. It is more affected by the intensity of the ultraviolet rays rather than the intensity of light itself per se. However, any air pollution, VOC, or odour that comes in contact with TiO2 coated surfaces will experience oxidation.

How does the air cleaning work?

The particles in the air are repeatedly brought into contact with the surfaces by natural air convection and movement. When these particles strike the nanoAce TiO2 surfaces they are oxidized by the photocatalytic properties of titanium dioxide. Substances that are oxidized in the air include: nitrogen oxide (NOx), formaldehyde, benzene and other Volatile Organic Compounds (VOCs). Oxidation by-products are innocuous amounts of compounds like carbon dioxide, water and nitrates.

What have been some of the more popular applications of TiO2 nanocoatings?

Bathrooms, floor tiles, sinks, showers, car interiors, to remove and prevent tobacco odours, kitchen counters, furniture and carpets (especially if you have pets), curtains, mini-blinds, windows exposed to light, ceiling fans, car rims, white outdoor furniture, house gutters, concrete, brick, the list goes on and on.

Can TiO2 be applied to carpets?

Absolutely, and with great results! Carpets treated with TiO2 will resist not only odours and grime but will be more durable as well. For this reason, carpets and fabrics in trains and pubic transportation are now being treated with TiO2 in Japan with great results.

How does the odour elimination work?

The odour substances in the air travel with the circulating airflow over the treated surfaces, they are then oxidized to odourless compounds.

How long does it take for surfaces to dry?

A surface with TiO2 applied normally dries in 10 - 30 seconds. After this, rain or sprayed water will cause no damage or harm to the self-cleaning surface.

How durable are TiO2 nanocoatings?

Unless the surface is scrubbed with abrasive materials and ammonia, nanocoatings will last as long as the original surface itself. The durability can vary between five and ten years, however, the photocatalytic effect is unlimited unless the surface is altered (painted or wallpapered over).

Is TiO2 consumed by the photocatalytic process?

The TiO2 only works as a catalyst therefore it is not consumed in the oxidation process.

What happens if the treated surface is damaged?

Scratches and small marks do not reduce the efficacy of TiO2 nanoparticles. Usual effects of the weather do not wear away TiO2. It can only be removed by extreme influences of continuing scouring with an abrasive.

Why haven't I heard of this before?

You're not alone. Most of us have used Titanium Dioxide (TiO2) and may not have known it. Titanium dioxide is the naturally occurring oxide of titanium, and for centuries it has been used in a wide variety of applications including paint, sunscreen, cosmetics and food colouring, to name a few.

In 1967, an amazing discovery about titanium dioxide was discovered by Akira Fujishima, a graduate student working under the guidance of Professor Kenichi Honda at the University of Tokyo. The discovery known as the Honda-Fujishima effect, showed that when titanium dioxide irradiated with light, it absorbed the energy, enabling it to decompose water into hydrogen and oxygen. The ability to use light energy to promote a chemical reaction classified titanium dioxide as a photocatalyst. Titanium dioxide has become predominant in industrial applications when a photocatalyst is required.

What else is special about TiO2 coatings?

Superhydrophilic

Since our TiO2 particles are so small, they make surfaces superhydrophilic (water-loving), reducing the contact angle of water on the surface so it slides off, carrying the already oxidized contaminants and oils with it. This means less spotting, reduced cleaning costs, and faster evaporation.

UV Protection

TIO2 naonparticles coated on a surface provide good UV protection. Sunscreens have TiO2 in it to absorb damaging UV rays. Our nanocoating will protect paint, plastics and textiles by absorbing the damaging UV rays and using the energy to oxidize harmful organic matter. It helps prevent damage to the structure of the coated surface, and reduces fading and maintenance. It's kind of like sunscreen for your walls and furniture.

How clean do objects have to be before a TiO2 nanocoating is applied?

Buildings can be treated as long as they are reasonably clean, but they must be clear from moss, mould and algal growth. Normally a jet wash will achieve this unless there is heavy growth - then it needs a commercial treatment to rid the surface of contaminants. The facade must be completely dry before applying TiO2 nanoparticles. For car interiors, just a vacuuming will suffice as long as there are no large deposits of spilt liquid, stains or similar. Otherwise, a cursory run over with a microfibre cloth for dust removal is the only pre treatment required. Pre-cleaned and already vacuumed interior treatments takes about 15 minutes for a medium sized car. Regarding exterior areas, care has to be taken to ensure that there have been no organic based polish or finishing coats applied to the paint...every manufacturer is different so a test area needs to be done before treating any of these surfaces.

BACK